Introduction:

This platform is based on the several key technologies in IOTs. It is a flexible-to-deploy and easy-to-use system for manufacturing and logistics companies to integrate different entities from various levels. Users in manage level, executive level and frontline operators can interconnect real-timely, intercommunicate adaptively as well as interact seamlessly with each other. This platform aims to assist end-users in improving productivity, upgrading product quality, reducing waste of manufacturing resources, cutting down the logistic cost, reforming the supervision ability of cross-boundary transportation, and finally accelerating their responses to fluctuated market and frequent engineering changes.

Advantages:

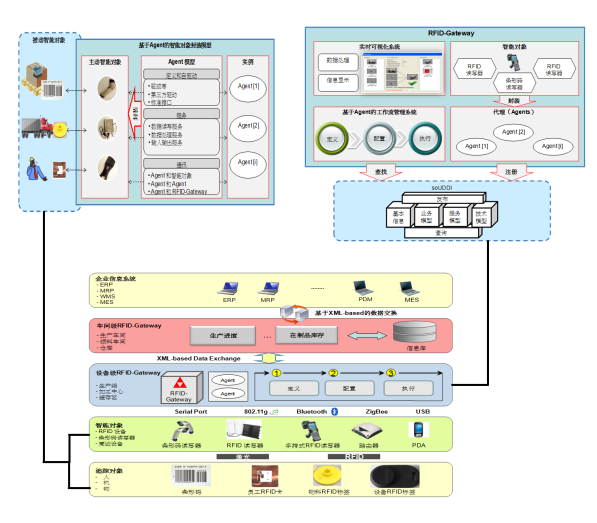

Manufacturing and logistics resources like machines, materials, trays, forklifts and operators are converted into smart objects (SOs) through barcode or RFID devices to create a ubiquitous environment. SOs are able to sense, interact and perform various manufacturing logics within the ubiquitous environment.

Diversified devices in IOTs can communicate with the platform by “plug and play” principle through wired or wireless standard. Work-cell gateway defines, configures and executes the dynamic workflows of frontline physical devices so that their working statuses and manufacturing logics could be carried out automatically.

The heterogonous information about manufacturing and logistics operations is integrated by shopfloor gateway to trace and track key events and objects. This critical information will be sent to other EISs for further decision-making through a data adapter.